Introduction to Industry 4.0 and AI

Industry 4.0, also known as the Fourth Industrial Revolution, is a term used to describe the current trend of automation and data exchange in manufacturing. It builds upon the third industrial revolution, which introduced computers and automation, but takes it further by integrating digital technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data.

AI, on the other hand, refers to the ability of machines to simulate human intelligence, including tasks such as problem-solving, reasoning, and learning. In manufacturing, AI can be used to optimize processes, predict maintenance needs, and improve quality control.

Implications for Manufacturing

The integration of Industry 4.0 and AI has significant implications for the manufacturing industry, including:

- Increased Efficiency: By automating processes and using AI to optimize them, manufacturers can achieve greater efficiency and productivity, reducing waste and increasing output.

- Improved Quality Control: AI can be used to monitor production processes in real-time, identifying defects and anomalies and making adjustments to prevent errors.

- Predictive Maintenance: By analyzing data from sensors and other sources, AI can predict when equipment is likely to fail, allowing for proactive maintenance and reducing downtime.

- Customization: Industry 4.0 technologies enable greater customization of products, as manufacturers can produce smaller batches with more unique features.

- Workforce Changes: While automation and AI can reduce the need for some jobs, they also require new skills and knowledge for workers to operate and maintain the technology.

- Data Security: The increased use of digital technologies in manufacturing also raises concerns about data security, as companies must ensure that sensitive information is protected from cyber threats.

Smart Manufacturing

Smart manufacturing is a concept that utilizes advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data to create a more efficient, flexible, and connected manufacturing process. It is a key component of Industry 4.0, the fourth industrial revolution that emphasizes the integration of digital technologies in manufacturing.

Applications of Smart Manufacturing

Smart manufacturing has numerous applications across the manufacturing industry, including:

- Predictive Maintenance: By using sensors and other data sources to monitor equipment and predict maintenance needs, manufacturers can reduce downtime and prevent costly repairs.

- Quality Control: Smart manufacturing can improve quality control by monitoring production processes in real-time, identifying defects, and making adjustments to prevent errors.

- Inventory Management: By utilizing data analytics and IoT sensors, smart manufacturing can help manufacturers optimize inventory levels and reduce waste.

- Customization: Smart manufacturing enables greater customization of products, allowing manufacturers to produce smaller batches with more unique features.

- Supply Chain Optimization: By utilizing data analytics and IoT sensors, smart manufacturing can help optimize supply chain operations, reducing lead times and improving delivery performance.

Benefits of Smart Manufacturing

The benefits of smart manufacturing include:

- Increased Efficiency: By optimizing processes and utilizing real-time data, smart manufacturing can increase efficiency and reduce waste.

- Improved Quality: Smart manufacturing can improve product quality by detecting and preventing defects in real-time.

- Greater Flexibility: Smart manufacturing enables greater flexibility in production, allowing manufacturers to quickly adjust to changing market demands.

- Cost Savings: By reducing waste, improving efficiency, and optimizing inventory levels, smart manufacturing can lead to significant cost savings.

Challenges of Smart Manufacturing

While smart manufacturing offers numerous benefits, it also presents some challenges, including:

- Data Security: The increased use of digital technologies in manufacturing raises concerns about data security, as sensitive information must be protected from cyber threats.

- Workforce Changes: Smart manufacturing requires new skills and knowledge for workers to operate and maintain the technology.

- Implementation Costs: Implementing smart manufacturing technology can require significant upfront costs, which may be a barrier for some manufacturers.

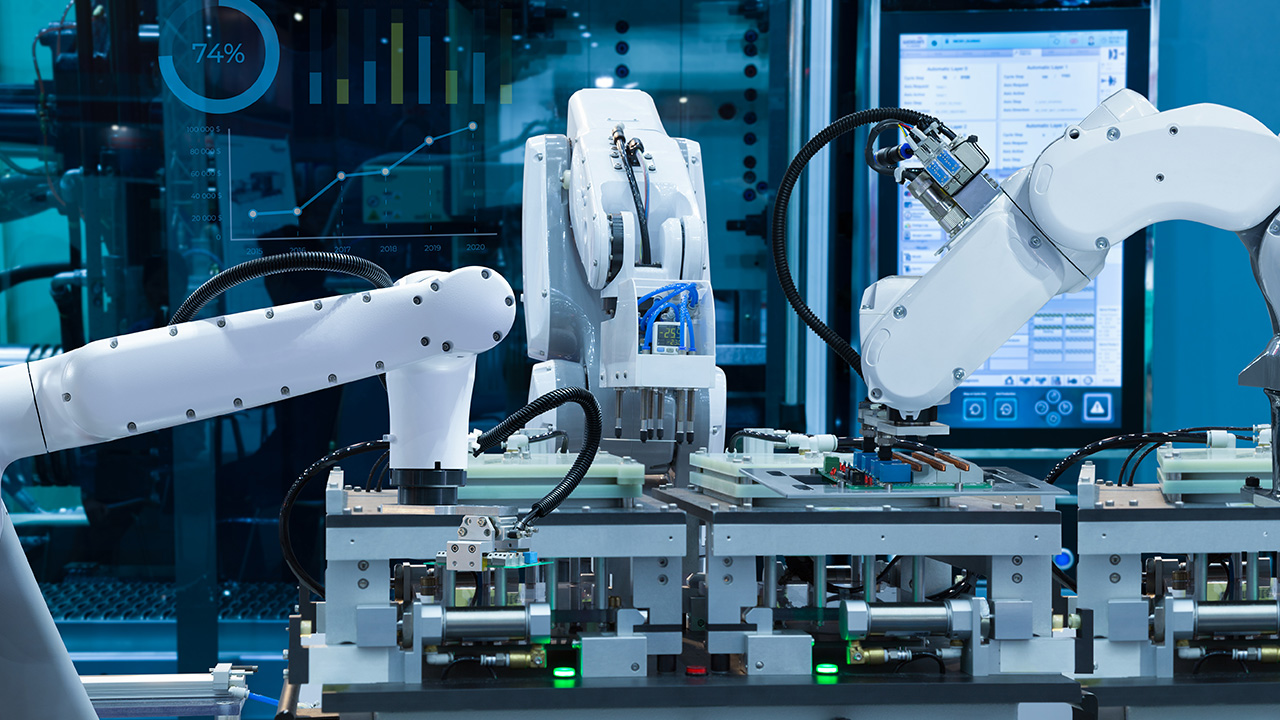

Robotics in Manufacturing

Robotics has been an integral part of the manufacturing industry for decades, but with advancements in technology, robots are becoming increasingly sophisticated and capable of performing more complex tasks. In recent years, the integration of robotics with artificial intelligence (AI) has further enhanced their capabilities, making them a key component of Industry 4.0.

Role of Robotics in Manufacturing

The role of robotics in manufacturing includes:

- Automation of Repetitive Tasks: Robots are used to automate repetitive tasks such as welding, painting, and assembly, improving efficiency and reducing the risk of human error.

- Improved Safety: Robots can be used to perform tasks that are dangerous or too difficult for humans to perform, reducing the risk of injury.

- Increased Productivity: Robots can work around the clock without breaks, increasing productivity and reducing production time.

- Customization: Robotics can enable greater customization of products, as robots can quickly and accurately perform complex tasks.

Integration of Robotics and AI

The integration of robotics with AI further enhances their capabilities, allowing for:

- Predictive Maintenance: By using sensors and data analytics, AI can predict when equipment is likely to fail, allowing for proactive maintenance and reducing downtime.

- Autonomous Robots: AI can enable robots to perform tasks autonomously, making decisions based on real-time data and adapting to changes in the production environment.

- Quality Control: AI can be used to monitor production processes in real-time, identifying defects and making adjustments to prevent errors.

- Collaborative Robots: AI can enable robots to work collaboratively with humans, performing tasks that require a combination of human and robot skills.

Benefits of Robotics and AI in Manufacturing

The benefits of robotics and AI in manufacturing include:

- Increased Efficiency: Robotics and AI can improve efficiency by automating tasks, reducing production time, and optimizing processes.

- Improved Quality: Robotics and AI can improve product quality by detecting and preventing defects in real-time.

- Greater Flexibility: Robotics and AI can enable greater flexibility in production, allowing manufacturers to quickly adjust to changing market demands.

- Cost Savings: Robotics and AI can lead to cost savings by reducing waste, improving efficiency, and optimizing inventory levels.

Challenges of Robotics and AI in Manufacturing

While robotics and AI offer numerous benefits for manufacturers, they also present some challenges, including:

- Implementation Costs: Implementing robotics and AI technology can require significant upfront costs, which may be a barrier for some manufacturers.

- Workforce Changes: Robotics and AI require new skills and knowledge for workers to operate and maintain the technology.

- Data Security: The increased use of digital technologies in manufacturing raises concerns about data security, as sensitive information must be protected from cyber threats.

Internet of Things (IoT) in Manufacturing

The Internet of Things (IoT) refers to the connection of physical objects to the internet, allowing them to send and receive data. In manufacturing, IoT technology is used to connect machines, sensors, and other devices, enabling real-time monitoring and control of the production process. IoT is a key component of Industry 4.0, which aims to digitize and automate manufacturing processes.

Applications of IoT in Manufacturing

The applications of IoT in manufacturing include:

- Predictive Maintenance: IoT sensors can be used to monitor machines and equipment, detecting anomalies and predicting when maintenance is needed. This can reduce downtime and increase productivity.

- Supply Chain Management: IoT technology can be used to track inventory levels, monitor shipments, and optimize logistics, improving supply chain efficiency.

- Quality Control: IoT sensors can be used to monitor production processes in real-time, detecting defects and making adjustments to prevent errors.

- Energy Management: IoT technology can be used to monitor energy consumption and optimize usage, reducing costs and improving sustainability.

Impact of IoT on Industry 4.0

The use of IoT in manufacturing is a key component of Industry 4.0, which aims to digitize and automate manufacturing processes. IoT technology enables real-time monitoring and control of the production process, providing valuable data that can be used to optimize operations and improve efficiency.

The impact of IoT on Industry 4.0 includes:

- Increased Efficiency: IoT technology enables real-time monitoring and control of the production process, allowing for greater efficiency and productivity.

- Improved Quality: IoT sensors can detect defects and make adjustments in real-time, improving product quality and reducing waste.

- Greater Flexibility: IoT technology can enable greater flexibility in production, allowing manufacturers to quickly adjust to changing market demands.

- Enhanced Data Analytics: IoT technology provides valuable data that can be used to optimize operations and make informed decisions.

Challenges of IoT in Manufacturing

While IoT technology offers numerous benefits for manufacturers, it also presents some challenges, including:

- Data Security: The increased use of digital technologies in manufacturing raises concerns about data security, as sensitive information must be protected from cyber threats.

- Implementation Costs: Implementing IoT technology can require significant upfront costs, which may be a barrier for some manufacturers.

- Workforce Changes: IoT technology requires new skills and knowledge for workers to operate and maintain the technology.

Big Data Analytics for Manufacturing

In recent years, big data analytics has emerged as a key technology for optimizing manufacturing processes. Big data analytics involves the analysis of large and complex data sets, allowing manufacturers to gain valuable insights and make informed decisions. In manufacturing, big data analytics can be used to optimize production processes, improve quality control, and enhance supply chain management.

Applications of Big Data Analytics in Manufacturing

The applications of big data analytics in manufacturing include:

- Predictive Maintenance: By analyzing data from sensors and machines, manufacturers can predict when maintenance is needed, reducing downtime and increasing productivity.

- Quality Control: Big data analytics can be used to analyze data from production processes in real-time, detecting defects and making adjustments to prevent errors.

- Supply Chain Management: By analyzing data from logistics and inventory management systems, manufacturers can optimize supply chain processes, improving efficiency and reducing costs.

- Product Design and Development: Big data analytics can be used to analyze customer feedback and market trends, allowing manufacturers to design products that better meet customer needs.

Impact of Big Data Analytics on Manufacturing

The use of big data analytics in manufacturing has numerous benefits, including:

- Increased Efficiency: By providing real-time data insights, big data analytics can help manufacturers optimize production processes and improve efficiency.

- Improved Quality: By detecting defects and making adjustments in real-time, big data analytics can help manufacturers improve product quality and reduce waste.

- Enhanced Supply Chain Management: By analyzing data from logistics and inventory management systems, manufacturers can optimize supply chain processes, improving efficiency and reducing costs.

- Better Decision Making: By providing valuable insights and data, big data analytics can help manufacturers make informed decisions about production processes, product design, and more.

Challenges of Big Data Analytics in Manufacturing

While big data analytics offers numerous benefits for manufacturers, it also presents some challenges, including:

- Data Quality: To be effective, big data analytics requires high-quality data. Manufacturers must ensure that data is accurate and reliable.

- Data Security: The use of digital technologies in manufacturing raises concerns about data security, as sensitive information must be protected from cyber threats.

- Implementation Costs: Implementing big data analytics can require significant upfront costs, which may be a barrier for some manufacturers.

Machine Learning for Manufacturing

Machine learning is a branch of artificial intelligence that involves the use of algorithms to analyze data, identify patterns, and make predictions. In manufacturing, machine learning can be used to optimize production processes, improve quality control, and enhance supply chain management.

Applications of Machine Learning in Manufacturing

The applications of machine learning in manufacturing include:

Predictive Maintenance: By analyzing data from sensors and machines, machine learning algorithms can predict when maintenance is needed, reducing downtime and increasing productivity.

- Quality Control: Machine learning algorithms can be trained to analyze data from production processes in real-time, detecting defects and making adjustments to prevent errors.

- Supply Chain Management: By analyzing data from logistics and inventory management systems, machine learning algorithms can optimize supply chain processes, improving efficiency and reducing costs.

- Production Optimization: Machine learning algorithms can be used to analyze production data and identify areas for improvement, such as reducing waste and increasing throughput.

Impact of Machine Learning on Manufacturing

The use of machine learning in manufacturing has numerous benefits, including:

- Increased Efficiency: By providing real-time data insights, machine learning can help manufacturers optimize production processes and improve efficiency.

- Improved Quality: By detecting defects and making adjustments in real-time, machine learning can help manufacturers improve product quality and reduce waste.

- Enhanced Supply Chain Management: By analyzing data from logistics and inventory management systems, machine learning can optimize supply chain processes, improving efficiency and reducing costs.

- Better Decision Making: By providing valuable insights and predictions, machine learning can help manufacturers make informed decisions about production processes, product design, and more.

Challenges of Machine Learning in Manufacturing

While machine learning offers numerous benefits for manufacturers, it also presents some challenges, including:

- Data Quality: To be effective, machine learning requires high-quality data. Manufacturers must ensure that data is accurate and reliable.

- Data Security: The use of digital technologies in manufacturing raises concerns about data security, as sensitive information must be protected from cyber threats.

- Implementation Costs: Implementing machine learning can require significant upfront costs, which may be a barrier for some manufacturers.

Language Processing for Manufacturing - Explores the use of natural language processing in manufacturing and its potential applications.

Natural Language Processing (NLP) is a branch of artificial intelligence that focuses on the interaction between humans and machines through natural language. In manufacturing, NLP can be used to improve communication, automate tasks, and optimize processes.

Applications of NLP in Manufacturing

The applications of NLP in manufacturing include:

- Quality Control: NLP can be used to analyze customer feedback, product reviews, and social media posts to identify patterns and improve product quality.

- Supply Chain Management: NLP can be used to analyze text data from logistics and inventory management systems to optimize supply chain processes, such as predicting demand and managing inventory.

- Maintenance and Repair: NLP can be used to improve communication between technicians and machines by enabling natural language interactions, such as voice commands and chatbots.

- Safety and Compliance: NLP can be used to analyze safety reports and compliance documentation to identify potential hazards and ensure regulatory compliance.

Impact of NLP on Manufacturing

The use of NLP in manufacturing has numerous benefits, including:

- Increased Efficiency: By automating tasks and improving communication, NLP can help manufacturers optimize production processes and improve efficiency.

- Improved Quality: By analyzing customer feedback and product reviews, NLP can help manufacturers improve product quality and reduce defects.

- Enhanced Supply Chain Management: By analyzing text data from logistics and inventory management systems, NLP can optimize supply chain processes, improving efficiency and reducing costs.

- Better Communication: By enabling natural language interactions between humans and machines, NLP can improve communication and reduce errors.

Challenges of NLP in Manufacturing

While NLP offers numerous benefits for manufacturers, it also presents some challenges, including:

- Data Quality: To be effective, NLP requires high-quality data. Manufacturers must ensure that data is accurate and reliable.

- Data Security: The use of digital technologies in manufacturing raises concerns about data security, as sensitive information must be protected from cyber threats.

- Language Barriers: NLP may struggle with different dialects, accents, and languages, which can be a challenge in global manufacturing environments.

Computer Vision for Manufacturing

Computer Vision is a field of artificial intelligence that focuses on enabling machines to interpret and understand visual information from the world around them. In manufacturing, computer vision can be used to improve quality control, automate processes, and enhance safety.

Applications of Computer Vision in Manufacturing

The applications of computer vision in manufacturing include:

- Quality Control: Computer vision can be used to detect defects and anomalies in products, improving product quality and reducing waste.

- Assembly and Packaging: Computer vision can be used to identify parts and components during assembly, ensuring accuracy and consistency. It can also be used to automate packaging processes.

- Maintenance and Repair: Computer vision can be used to identify equipment failures and wear-and-tear, enabling proactive maintenance and reducing downtime.

- Safety: Computer vision can be used to monitor manufacturing processes and identify potential safety hazards, such as employee accidents and equipment failures.

Impact of Computer Vision on Manufacturing

The use of computer vision in manufacturing has numerous benefits, including:

- Improved Quality: By detecting defects and anomalies in products, computer vision can help manufacturers improve product quality and reduce waste.

- Increased Efficiency: By automating processes and reducing downtime, computer vision can improve efficiency and reduce costs.

- Enhanced Safety: By monitoring manufacturing processes and identifying potential safety hazards, computer vision can improve workplace safety and reduce accidents.

- Better Data: By collecting and analyzing visual data, computer vision can provide manufacturers with insights into their operations, enabling better decision-making.

Challenges of Computer Vision in Manufacturing

While computer vision offers numerous benefits for manufacturers, it also presents some challenges, including:

- Data Quality: To be effective, computer vision requires high-quality data. Manufacturers must ensure that data is accurate and reliable.

- Integration: Integrating computer vision technology into existing manufacturing processes can be complex and time-consuming.

- Cost: Computer vision technology can be expensive to implement and maintain, particularly for small and medium-sized manufacturers.

Deep Learning for Manufacturing

Deep learning is a subset of machine learning that focuses on building neural networks that can learn and make predictions on complex data. In manufacturing, deep learning can be used to improve product design, quality control, and predictive maintenance.

Applications of Deep Learning in Manufacturing

The applications of deep learning in manufacturing include:

- Product Design: Deep learning can be used to analyze customer feedback, market trends, and historical data to improve product design.

- Quality Control: Deep learning can be used to identify defects and anomalies in products, improving product quality and reducing waste.

- Predictive Maintenance: Deep learning can be used to identify patterns in equipment data and predict potential failures, enabling proactive maintenance and reducing downtime.

- Supply Chain Optimization: Deep learning can be used to optimize the supply chain by analyzing data on demand, inventory, and production.

Impact of Deep Learning on Manufacturing

The use of deep learning in manufacturing has numerous benefits, including:

- Improved Product Design: By analyzing customer feedback, market trends, and historical data, deep learning can help manufacturers design products that better meet customer needs.

- Increased Efficiency: By improving quality control and enabling proactive maintenance, deep learning can improve efficiency and reduce costs.

- Enhanced Safety: By predicting equipment failures and identifying potential safety hazards, deep learning can improve workplace safety and reduce accidents.

- Better Data: By collecting and analyzing data on equipment performance, production, and supply chain, deep learning can provide manufacturers with insights into their operations, enabling better decision-making.

Challenges of Deep Learning in Manufacturing

While deep learning offers numerous benefits for manufacturers, it also presents some challenges, including:

- Data Quality: To be effective, deep learning requires high-quality data. Manufacturers must ensure that data is accurate and reliable.

- Integration: Integrating deep learning technology into existing manufacturing processes can be complex and time-consuming.

- Cost: Deep learning technology can be expensive to implement and maintain, particularly for small and medium-sized manufacturers.

Autonomous Systems for Manufacturing

Autonomous systems, such as robots and drones, have been increasingly used in manufacturing to automate production processes, reduce labour costs, and improve efficiency. These systems can be used for a variety of tasks, including material handling, assembly, inspection, and maintenance. In this article, we will explore the use of autonomous systems in manufacturing and their potential impact on the industry.

Applications of Autonomous Systems in Manufacturing

The applications of autonomous systems in manufacturing include:

- Material Handling: Autonomous mobile robots can be used to move raw materials and finished products around the factory floor, reducing the need for human operators.

- Assembly: Autonomous systems can be used to perform repetitive assembly tasks, such as inserting screws and nuts, reducing the need for manual labour.

- Inspection: Autonomous systems can be used to inspect products for defects and anomalies, improving quality control and reducing waste.

- Maintenance: Autonomous systems can be used to perform routine maintenance tasks, such as cleaning and lubricating machinery, reducing downtime.

Impact of Autonomous Systems on Manufacturing

The use of autonomous systems in manufacturing has numerous benefits, including:

- Improved Efficiency: By automating production processes, autonomous systems can improve efficiency and reduce labour costs.

- Increased Safety: By reducing the need for human operators in dangerous or hazardous environments, autonomous systems can improve workplace safety.

- Better Quality Control: By performing inspections and identifying defects, autonomous systems can improve product quality and reduce waste.

- Enhanced Flexibility: Autonomous systems can be programmed to perform a variety of tasks, making them more flexible than traditional production systems.

Challenges of Autonomous Systems in Manufacturing

While autonomous systems offer numerous benefits for manufacturers, they also present some challenges, including:

- Cost: Autonomous systems can be expensive to purchase and maintain, particularly for small and medium-sized manufacturers.

- Integration: Integrating autonomous systems into existing production processes can be complex and time-consuming.

- Security: Autonomous systems can be vulnerable to cyber-attacks, which can have serious consequences for production processes.

- Legal and Ethical Issues: The use of autonomous systems raises legal and ethical issues, particularly around liability in the event of accidents or malfunctions.

Cybersecurity in Manufacturing

With the rise of Industry 4.0 and the integration of technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data Analytics in manufacturing, the risk of cyber-attacks has become a growing concern for the industry. Cyber-attacks can disrupt production processes, compromise sensitive data, and cause significant financial losses. Therefore, it is crucial for manufacturers to prioritize cybersecurity and implement measures to prevent cyber-attacks. In this article, we will examine the importance of cybersecurity in manufacturing and how it can be integrated into Industry 4.0.

Importance of Cybersecurity in Manufacturing

Manufacturing organizations are prime targets for cyber-attacks due to the potential financial gains from stealing trade secrets, intellectual property, and sensitive data. Cyber-attacks can also cause significant damage to manufacturing equipment and disrupt production processes, leading to financial losses and reputational damage. Therefore, the importance of cybersecurity in manufacturing cannot be overstated. Some key reasons why cybersecurity is critical for manufacturing include:

- Protection of Intellectual Property: Manufacturers invest significant resources in research and development to create unique products and processes. Protecting intellectual property is essential for maintaining a competitive edge.

- Maintenance of Production Processes: Cyber-attacks can disrupt production processes, causing downtime and production delays.

- Protection of Sensitive Data: Manufacturing organizations store sensitive data such as financial information, customer data, and employee data. Cybersecurity measures are essential to protect this data from unauthorized access.

- Compliance: Many industries have regulatory requirements for data privacy and cybersecurity. Manufacturers must comply with these regulations to avoid legal and financial consequences.

Integrating Cybersecurity into Industry 4.0

The integration of technologies such as the IoT, AI, and Big Data Analytics in manufacturing has made cybersecurity even more critical. Manufacturers can integrate cybersecurity measures into their Industry 4.0 strategy by:

- Conducting Risk Assessments: Manufacturers should conduct regular risk assessments to identify vulnerabilities and potential threats.

- Implementing Access Controls: Access controls such as password policies, two-factor authentication, and biometric authentication can prevent unauthorized access to sensitive data and systems.

- Monitoring Networks and Systems: Manufacturers should monitor their networks and systems for anomalies and potential threats using tools such as intrusion detection systems and security information and event management (SIEM) systems.

- Educating Employees: Employees can be the weakest link in cybersecurity. Educating employees about cybersecurity best practices can reduce the risk of human error.

- Implementing Incident Response Plans: Manufacturers should have a plan in place to respond to cyber-attacks quickly and effectively.

Case Studies

Artificial intelligence (AI) has become an increasingly important tool in manufacturing, with its potential to improve efficiency, quality, and safety. In this article, we will explore several case studies that demonstrate successful implementation of AI in manufacturing.

General Electric (GE) - Predictive Maintenance

General Electric has implemented predictive maintenance in its wind turbines to improve their reliability and reduce downtime. By analyzing data from sensors in the turbines, GE's AI system can predict when maintenance is required, allowing technicians to perform maintenance before a failure occurs. This approach has improved turbine reliability and reduced maintenance costs, ultimately leading to increased revenue.

BMW - Quality Control

BMW uses computer vision to inspect the surface quality of its car bodies. The system analyzes images of the car body to detect defects such as scratches and dents. By using AI, BMW can detect defects that may be missed by human inspectors, leading to improved quality control and ultimately a better product for the customer.

Airbus - Supply Chain Optimization

Airbus uses AI to optimize its supply chain by predicting which parts will be required for production and when. By analyzing data from multiple sources, including customer orders and supplier delivery times, Airbus can predict which parts will be required and when they will be needed. This approach has reduced inventory costs and improved production efficiency.

Toyota - Predictive Analytics

Toyota has implemented predictive analytics in its factories to optimize production processes. By analyzing data from sensors and other sources, Toyota's AI system can predict which machines are likely to fail and when, allowing maintenance to be scheduled in advance. This approach has reduced downtime and improved production efficiency.

Procter & Gamble (P&G) - Supply Chain Optimization

P&G uses AI to optimize its supply chain by predicting demand for its products. By analyzing data from multiple sources, including point-of-sale data and social media activity, P&G can predict which products are likely to be in high demand and adjust its production accordingly. This approach has reduced inventory costs and improved customer satisfaction.

In conclusion, these case studies demonstrate the successful implementation of AI in manufacturing. By using AI to optimize production processes, improve quality control, and reduce downtime, companies can achieve significant cost savings and improve customer satisfaction. As AI technology continues to develop, it is likely that we will see more companies adopting AI in manufacturing in the future.